A 2.4-metre base frame arrives on the shop floor. At first glance, it appears relatively straightforward. However, once it reaches the CMM table, the true challenge becomes clear. Positional tolerances must hold across the full length. Mating faces need consistent parallelism from one end of the component to the other. A late design change has also introduced a new pocket that must now be integrated without compromising stability or accuracy.

At this scale, machining is no longer simply a matter of programming the part and pressing the cycle start button. The approach either protects the geometry and the lead time, or it magnifies every variable in the process.

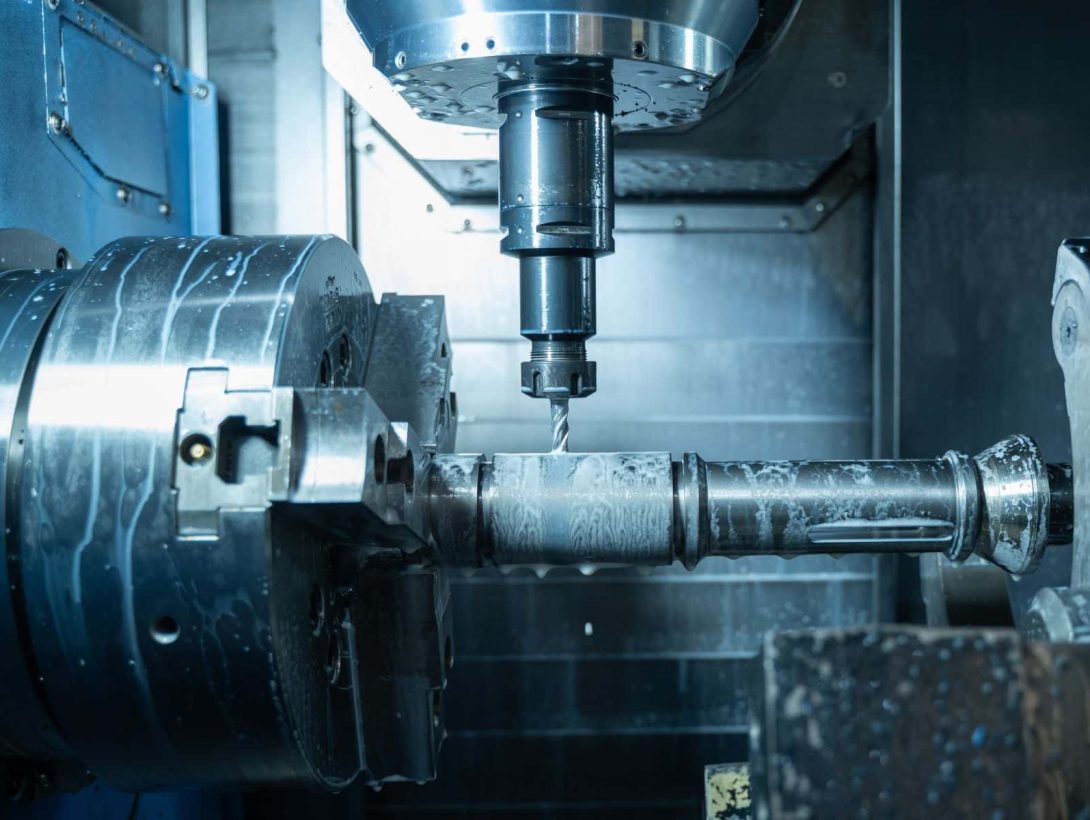

This is where large-format CNC milling provides value through controlled accuracy at size.

Table of Contents

- Executive Summary

- When Big Components Go Wrong

- 5 Benefits You Actually Feel in Production

- How We Engineer Accuracy at Size

- Machines That Make the Difference

- Buyer’s Checklist: Choosing a Large-Format Milling Partner

- Conclusion

- Talk to Our Team

Executive Summary

Large-format CNC milling enables precise machining of oversized and complex components while maintaining geometric integrity, surface quality and repeatability. The value is not simply the physical ability to hold large workpieces. It is the combination of machine rigidity, thermal stability, metrology, tooling strategy and controlled material removal that ensures accuracy across the entire part.

In short, the performance comes from process capability supported by the right machine platform.

When Big Components Go Wrong

When components increase in size, small errors become large problems. A slight angular deviation at one end can result in significant misalignment at the opposite side. If a component needs to be repositioned partway through machining, each re-clamping risks losing the original datum reference. Tool deflection and vibration also become more noticeable on long surfaces, creating taper, variation or contour inconsistency.

These issues highlight why machining large workpieces requires planning, metrology and stability, rather than reactive correction later.

5 Benefits You Actually Feel in Production

1) Precision maintained across the whole workpiece

Large-format CNC machines are designed with heavy, stable beds and rigid guideways that support accuracy over extended travels. This stability ensures that the relationship between surfaces, bores and datums remains consistent across the entire component, not just near the spindle.

2) Single-setup machining that reduces error

Completing major features in a single setup significantly reduces the risk of accumulated misalignment. This approach shortens machining time, improves inspection results and reduces the need for downstream adjustment or rework.

3) Capability to produce complex geometry at scale

Many large industrial components now require deep pockets, contoured faces and multi-plane features. Multi-axis large-format machines allow these forms to be created directly and accurately, avoiding the compromises and manual blending that can occur when capacity is restricted.

4) Lead times that remain stable even during design revision

Programmed probing routines, adaptive offsets, and secure fixturing allow late-stage design changes to be incorporated without a complete restart. This reduces stoppage time and keeps project schedules on track.

5) Traceable repeatability for regulated industries

Probing, inspection workflows and dynamic compensation create a documented machining history for every component. This level of traceability is essential in aerospace, defence, power generation and high-value industrial equipment.

How We Engineer Accuracy at Size

Precision in large-format machining is achieved through several linked practices:

Datum strategy

Datums are selected to support alignment across the entire part. This ensures that geometric relationships remain intact through every toolpath stage.

Material removal planning

Roughing and finishing sequences are designed to manage internal stresses and prevent movement as material is removed.

On-machine metrology

Probing is used to locate features, confirm alignment and adjust offsets during machining, rather than after it.

Fixturing for stability

Fixtures are designed to support the weight and shape of the component without over-constraining it, maintaining rigidity while allowing full machining access.

Toolpath and tooling optimisation

Cutting strategies are selected to minimise vibration, maintain surface condition and control deflection over long tool lengths.

Machines That Make the Difference

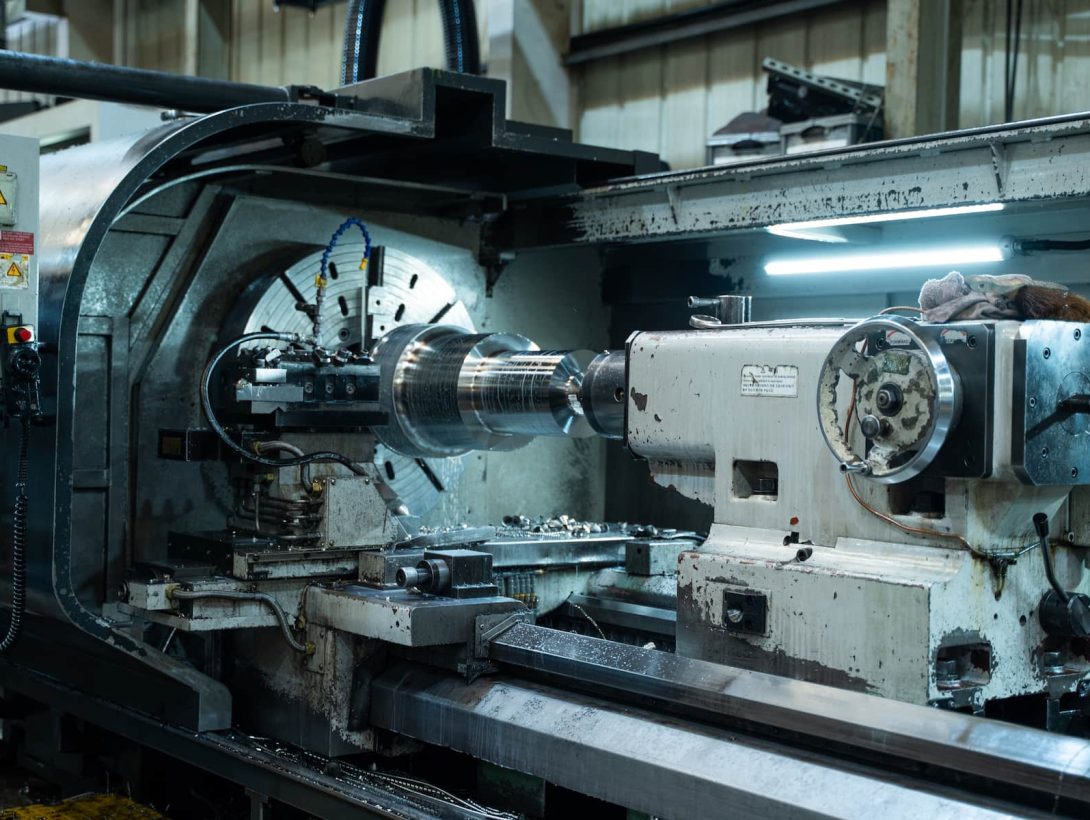

At Mollart Cox, our large-format milling capability is supported by machine platforms engineered for rigidity, stability and controlled accuracy across long travels.

Correa Norma (In Production)

The Correa Norma provides the structural rigidity and reach required to machine large components with demanding geometric relationships. Its stability enables precision over extended distances, making it ideal for parts that require alignment accuracy across multiple faces or surfaces.

Correa Axia (In Production)

The existing Correa Axia is a core part of our milling operation. It offers increased stiffness, enhanced thermal stability and high-power spindle performance, enabling the efficient machining of large components without compromising surface quality or positional accuracy. This machine supports both single-setup strategies and the controlled removal required for deep or complex geometries.

Additional Correa Axia (Arriving Summer 2026)

A second Correa Axia will be installed next Summer to expand capacity and throughput further. This investment strengthens our ability to support larger production volumes and more complex components while maintaining short, stable lead times and repeatable dimensional integrity.

Buyer’s Checklist: Choosing a Large-Format Milling Partner

Look for suppliers that can demonstrate:

- A clear datum and inspection approach

- One-setup strategies where possible

- On-machine probing with recorded results

- Management of heat and tool deflection

- Fixturing that supports both access and stability

- Inspection workflows matched to GD&T requirements

Capacity is important, but process control is what protects tolerance and schedule.

Conclusion

Large-format CNC milling offers accurate, controlled machining for components where size and complexity are defining factors. When combined with stable fixturing, intelligent toolpath development and digital metrology, the process delivers high-integrity parts with repeatable results and reliable lead times.